There is nothing more certain in a datacenter than End of Life product management, where old equipment needs to be cycled out and replaced with newer hardware. This is especially true with battery backup systems, where the core component is generally a sealed lead acid (SLA) battery, which has a usable life between 3-5 years. While you can't rip out the guts of a server and make it "new" again, you can do just that with an enterprise battery backup system. In this In the Lab article, we replace the battery pack in an Eaton 9PX UPS that has been serving our lab for the past six years.

There is nothing more certain in a datacenter than End of Life product management, where old equipment needs to be cycled out and replaced with newer hardware. This is especially true with battery backup systems, where the core component is generally a sealed lead acid (SLA) battery, which has a usable life between 3-5 years. While you can't rip out the guts of a server and make it "new" again, you can do just that with an enterprise battery backup system. In this In the Lab article, we replace the battery pack in an Eaton 9PX UPS that has been serving our lab for the past six years.

Generally speaking, datacenter-grade battery backup systems are designed to out-live the useful life of the backup batteries contained within them. This means its not uncommon for a UPS, PDU and associated power equipment to last far longer than a traditional server or storage product, which will become outdated well before it breaks or runs into problems. All of the Eaton UPS models are designed with this in mind and they offer replacement battery packs to swap out for a fraction of the cost compared to replacing the entire UPS. In the case of our Eaton 9PX6K, which has a street price of around $4,000, the battery back is only $500. This cost-effective replacement pack gives the UPS an additional 3-5 years of service life, without requiring a complete forklift upgrade or downtime.

To prepare the Eaton 9PX for its replacement battery, start by putting the UPS into bypass mode through the control panel. This forces it to pass facility power, bypassing the internal dual conversion AC > DC > AC circuit and lets the battery pack be safely removed. Once the unit is in bypass mode, pop off the front cover surrounding the LCD, remove two Phillips head screws and pivot the front cover off to the side.

With the front cover out of the way, the battery pack can be seen braced in with a metal bracket. Remove the two screws securing this bracket in place. Once the bracket is removed, slide the battery pack out of the chassis. Be careful with this step, since in the case of the 9PX battery is a 60lb case of plastic and lead.

After removing the original battery, slide the new battery pack into position and fully seat it inside the chassis. During this step the UPS will warn you that no battery is present. This error will clear in a few seconds. The connector will self-center and connect itself without user intervention. This is a helpful safety feature since you don't need to mess with any wiring directly. With the pack in position, secure the original bracket back into place and finally put the front cover back into its original position.

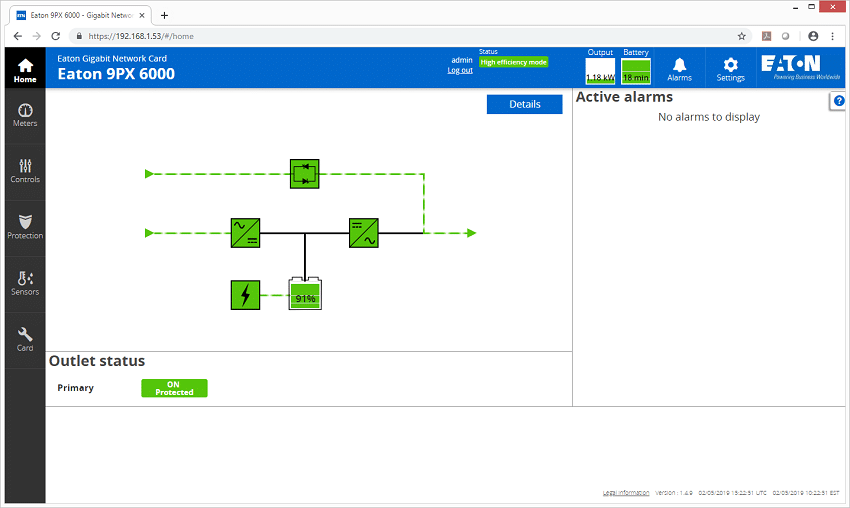

With unit closed back up, go back to the same menu and change the UPS mode to normal. This removes it from bypass mode, self-checks the battery and puts the UPS back to work idling off in the background unit it needs to save the day.

Sign up for the StorageReview newsletter