CoolIT Systems aims to revolutionize data center cooling with its latest high-capacity and scalable Coolant Distribution Units.

CoolIT Systems has launched three new Coolant Distribution Units (CDUs): the AHx240, AHx180, and CHx500. These new models are tailored to meet diverse cooling requirements and offer scalable, high-capacity solutions for various data center applications.

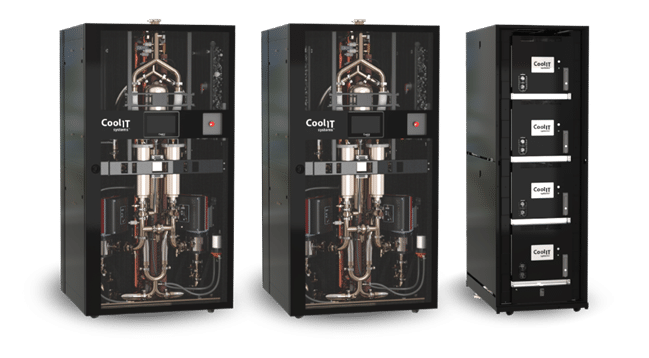

CoolIT Coolant Distribution Units (from left to right): AHx180, AHx240 and CHx500

All three CDUs are engineered to meet the demanding cooling requirements of AI, high-performance computing, and enterprise computing applications. They provide exceptional performance, density, efficiency, and reliability, especially when integrated with servers containing CoolIT’s OMNI cold plates with Split-Flow technology and CoolIT manifolds. The company has designed these units to deliver the highest flow rates necessary for cutting-edge AI systems while ready to set new industry standards.

The AHx240 and AHx180 set new standards in liquid-to-air CDUs. The AHx240 is the industry’s highest-capacity CDU, providing over 240 kW in a 2-rack footprint, while the AHx180 delivers 180 kW with a design optimized to operate within standard data center airflow ranges. These self-contained systems eliminate the need for external facility water and enable data center operators to deploy the highest-density AI workloads without the high cost of investing in new infrastructure. The AHx240 liquid-to-air CDU can cool up to four NVIDIA GB200 racks, while the AHx180 can cool up to two.

CoolIT’s CHx500 liquid-to-liquid CDU provides scalable cooling for high-density computational workloads. Four CHx500 units can be stacked to deliver 2MW heat management in a single rack. The CHx500 platform is the highest-performance, highest-density liquid-to-liquid CDU available. Supporting ASHRAE W45 cooling facilitates efficient heat reuse and sets a new standard for sustainable, high-performance data center cooling solutions. The CHx500 x 4 (full stack, one rack) liquid-to-liquid CDU will cool up to 58 racks of 21 x 2U DLC servers (at 14.7 kW per rack) or 1,218 DLC servers.

Features

| AHx180 Liquid-to-Air CDU | AHx240 Liquid-to-Air CDU | CHx500 Liquid-to-Liquid CDU |

| 180 kW cooling capacity at 15°C approach. | 240 kW cooling capacity at 15°C approach. | 500 kW cooling capacity at 5.5°C approach. |

| 2 x high-performance pumps. | 2 x high-performance pumps. | 3 pumps for N+1 redundancy. |

| 4 x high-efficiency fans. | 8 x high-efficiency fans. | Two A+B redundant, hot-swappable power supplies. |

| All stainless-steel piping. | All stainless-steel piping. | ASHRAE W45 warm water cooling capable. |

| Slim 2-rack footprint (1200 mm W x 1066 mm D / 47.2″ W x 41.9″ D). | 2-rack footprint (1200 mm W x 1200 mm D / 47.2″ W x 47.2″ D). | 11U height, allowing 4 CDU units + 3U coolant reservoir in single 48U rack. |

| Integrated sensors: flow, pressure, temperature, humidity, coolant level and leak detection. | Built-in sensors: flow, pressure, temperature, humidity, coolant level and leak detection | Built-in sensors: flow, pressure, temperature, humidity, coolant level and leak detection. |

| Integrated 50 µ serviceable filter with 25 µ to 150 µ options. | Integrated 50 µ serviceable filter with 25 µ to 150 µ options. | Optional 50 µ external filter |

| Group control for up to 20 units. | Group control for up to 20 units. | Group control for up to 4 units in 1 rack. |

| Integrated control and monitoring system (Redfish, SNMP, TCP/IP, Modbus, BACnet and others). | Integrated control and monitoring system (Redfish, SNMP, TCP/IP, Modbus, BACnet and others). | Integrated control and monitoring system (SSH, SNMP, TCP/IP, Modbus and others). |

| PLC-based control system with 10″ front panel touchscreen. | PLC-based control system with 10″ front panel touchscreen. | Built-in 7″ front panel touchscreen. |

| Multi-language support. | Multi-language support. | Multi-language support |

| Integrated fill pumps and reservoir. | Integrated fill pumps and reservoir. | Integrated fill pumps and reservoir. |

| Redundant pumps (2N) and fan (N+1). | Redundant pumps (2N) and fans (N+1). | Redundant pumps (N+1) and power supplies |

| Optional ATS. | Optional ATS. | |

| Field replaceable fans, pumps, piping and sensors. | Field replaceable fans, pumps, piping and sensors. | All stainless-steel piping |

| Easily accessible drain and reservoir tanks. | Easily accessible drain and reservoir tanks. | Easily accessible drain and reservoir tanks |

We reviewed CoolIT Systems in May and retrofitted a Dell PowerEdge R760 with CoolIT’s cold plates, manifold, and L2A CDU. Our findings revealed significant benefits, including dramatically reducing fan usage and electricity consumption. The DLC configuration also resulted in cooler CPU temperatures and a slight performance boost. This setup highlights the growing necessity of liquid cooling for modern, high-power AI and computational workloads, providing efficiency and performance enhancements in data center environments.

Availability

Manufactured in CoolIT’s new Canadian facility, AHx240, AHx180, and CHx500, are now available for immediate shipping. This expansion is part of the company’s strategy for the growing demand for efficient and reliable liquid cooling solutions, driven by the increasing power of AI processors and the need for higher-density server workloads. With these new CDUs, CoolIT solidifies its position as a market leader in advanced cooling solutions for modern data centers.

Engage with StorageReview

Newsletter | YouTube | Podcast iTunes/Spotify | Instagram | Twitter | TikTok | RSS Feed