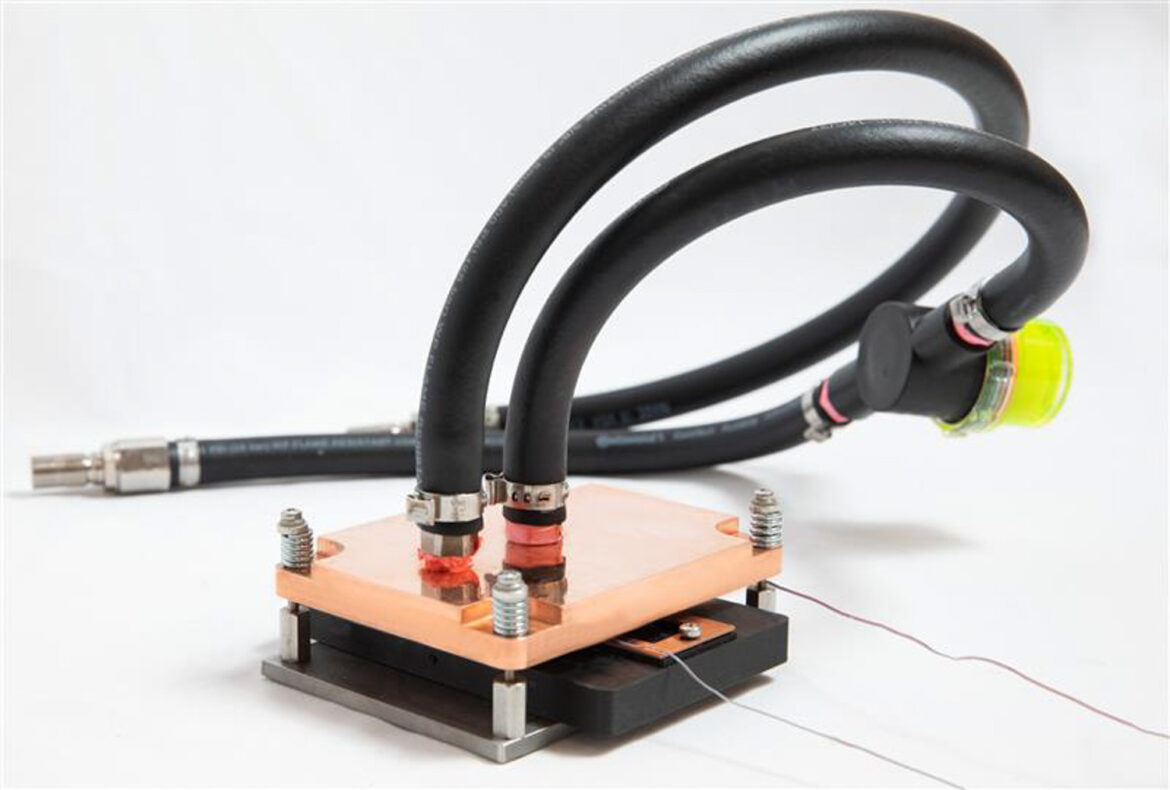

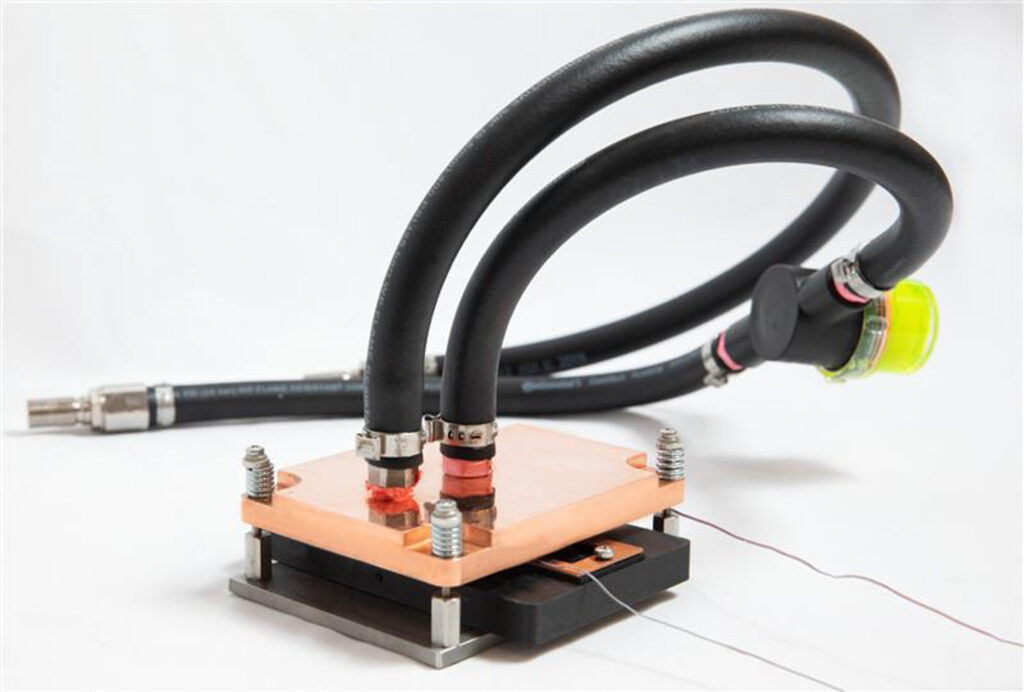

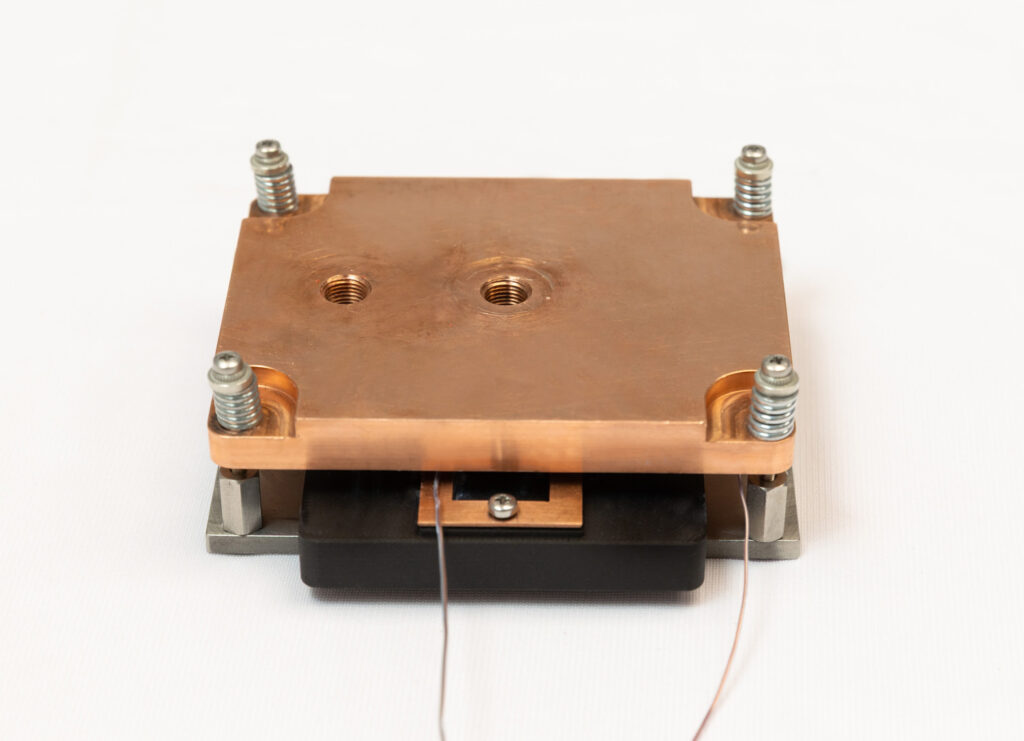

CoolIT’s new 4000W cold plate pushes the limits of single-phase liquid cooling, enabling AI and HPC processors to run cooler and more efficiently.

CoolIT Systems has raised the bar in high-performance liquid cooling, unveiling a new 4000W-ready single-phase direct liquid cooling (DLC) cold plate. This latest advancement doubles the previously accepted thermal limits of single-phase DLC, reinforcing its position as the industry’s most mature and scalable cooling solution for high-wattage AI and HPC processors.

“CoolIT continues to lead the industry in performance. We are thrilled to show silicon leaders that single-phase DLC will continue to be a key enabling technology with demonstrated capability for up to 4000W processors,” said Kamal Mostafavi, VP of Engineering at CoolIT. “Single-phase direct liquid cooling – known for being the most mature, reliable, and scalable liquid cooling technology – is also more than capable of cooling ultra-high watt microprocessors for the foreseeable future.”

Single-Phase DLC Advancements

Single-phase DLC removes heat from semiconductors using water or a water-glycol mixture running through coldplates mounted directly to chips. This method has become popular for large IT vendors like Dell, Lenovo, HPE, and others who offer high-power AI and HPC systems. In testing, CoolIT’s latest coldplate captured over 97% of heat from a 4000W thermal test vehicle (TTV) at a flow rate of 6 liters per minute (LPM), equivalent to 1.5 LPM per kW—aligning with the semiconductor industry’s recommended flow rate for high-wattage chips.

Thermal resistance is another critical factor in high-performance cooling, and CoolIT’s 4000W coldplate achieves an ultra-low thermal resistance of Tr<0.009 C/W, while keeping the full-loop pressure drop—including fittings and quick disconnects—at just 8 PSI. The company’s Split-Flow technology improves thermal and flow performance by 30% compared to standard coldplates, ensuring targeted cooling for the hottest areas of modern processors.

CoolIT 4000W Cold Plate

StorageReview previously evaluated CoolIT’s tiny CDU and cold plates in a Dell server, testing its real-world performance and efficiency in enterprise environments. Even our modest testing shows the potential of liquid cooling even on compute servers where we showed a 200W savings in a single system when comparing DLC to air cooling.

The Industry is Full of Options

While CoolIT continues to push the boundaries of single-phase DLC, other liquid cooling approaches have also been making strides. StorageReview.com has explored technologies like Chilldyne’s negative pressure liquid cooling, which mitigates leak risks by keeping coolant under vacuum, and ZutaCore’s two-phase direct-to-chip cooling, which leverages phase-change technology for improved heat dissipation in dense server environments. Additionally, Castrol’s dielectric immersion cooling presents a compelling alternative: submerging entire systems in non-conductive fluid, reducing the need for complex plumbing. Each solution has advantages depending on deployment scale, thermal requirements, and infrastructure constraints.

That said, water-based DLC remains the most widely adopted liquid cooling method, accounting for over 60% of the data center liquid cooling market due to its cost-effectiveness and high thermal efficiency (Market Research Future). With AI and high-density computing driving demand, direct-to-chip cooling solutions now dominate, holding a 66.78% market share as data centers push for greater efficiency (Mordor Intelligence).

For more details and to download CoolIT’s technical brief on the 4000W cold plate, visit CoolIT Systems.

Engage with StorageReview

Newsletter | YouTube | Podcast iTunes/Spotify | Instagram | Twitter | TikTok | RSS Feed