NVIDIA has announced that leading Taiwanese electronics manufacturers are leveraging its technology to transform their factories into more autonomous facilities using a new reference workflow. This innovative workflow integrates NVIDIA Metropolis vision AI, NVIDIA Omniverse for physically based rendering and simulation, and NVIDIA Isaac AI for robot development and deployment.

The new workflow allows manufacturers to create digital twins for real-time simulation of various factory layouts. This capability helps optimize space, processes, and efficiency without incurring the costs associated with physical changes. Deepu Talla, Vice President of Robotics and Edge Computing at NVIDIA, highlighted the significance of this advancement: “AI for manufacturing is here. Every factory is becoming more autonomous due to the transformational impact of generative AI and digital twin technologies. With NVIDIA Omniverse, Metropolis, and Isaac, the industrial ecosystem can accelerate its adoption of autonomous technologies, enhancing operational efficiencies and reducing costs.”

Prominent electronics manufacturers, including Delta Electronics, Foxconn, Pegatron, and Wistron, are implementing this reference workflow to build, simulate, and operate their robotics-enhanced facilities.

Digital Twin Innovation

Foxconn operates more than 170 factories globally, with the latest being a virtual plant pushing the state of the art in industrial automation. During a COMPUTEX keynote, NVIDIA founder and CEO Jensen Huang demonstrated Foxconn’s use of NVIDIA Omniverse to develop digital twins of its factories. This platform integrates 3D data from industry tools such as Siemens Xcelerator’s Teamcenter. Foxconn utilizes Omniverse to optimize equipment layout for operational flow and employs NVIDIA Metropolis for AI-driven worker safety monitoring. These digital twins are virtual training environments to simulate, test, and validate autonomous mobile robots (AMRs) and AI robot manipulation arms powered by NVIDIA Isaac technologies. Foxconn’s CEO and Chairman, Young Liu, emphasized the revolutionary potential of AI and robotics in manufacturing, enhancing safety and driving operational efficiencies.

Smart Green Solutions

Delta Electronics uses NVIDIA Isaac Sim, an extensible robotics simulation platform built on Omniverse and OpenUSD, to integrate demo production lines virtually. This platform generates photorealistic synthetic data to train computer vision models for its NVIDIA Metropolis-powered automatic optical inspection (AOI) and defect detection solutions.

Real-Time Factory Optimization

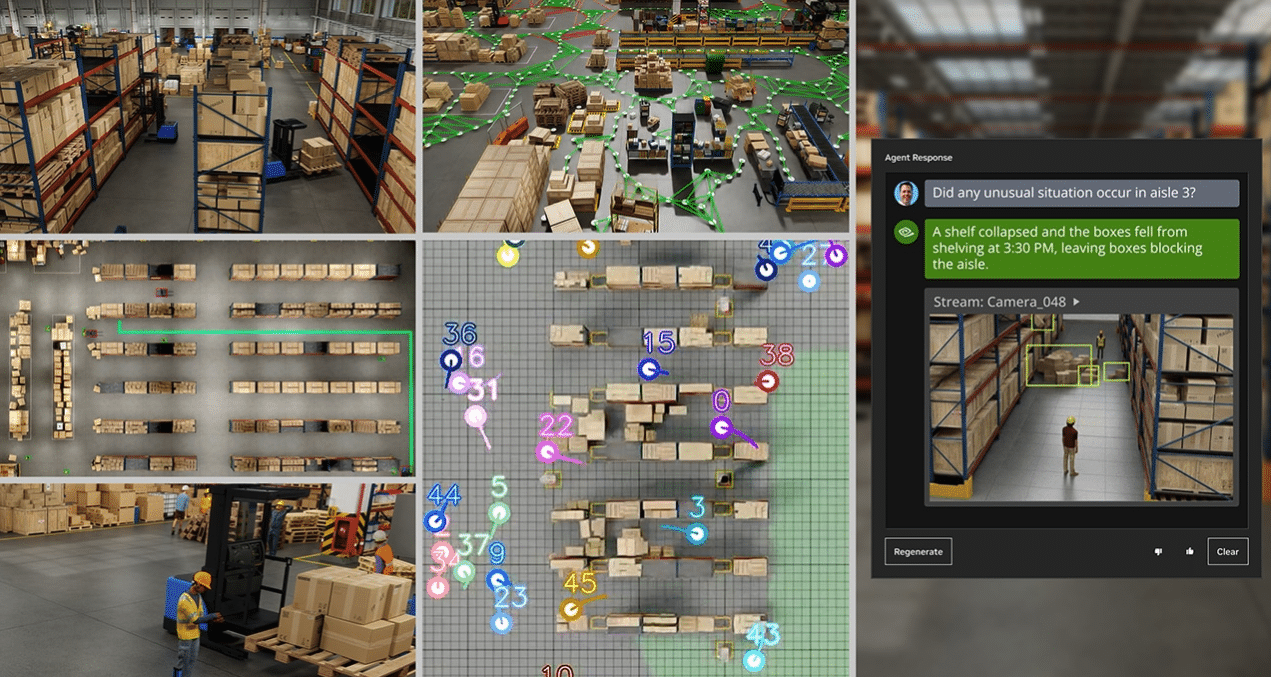

Pegatron is deploying an NVIDIA Metropolis multi-camera workflow and launching services that connect its NVIDIA Omniverse and Metropolis factory digital twin workflow with NVIDIA NeMo and NVIDIA NIM. This integration enables real-time communication with factory operators, improving worker safety and productivity across Pegatron’s extensive factory network.

Accelerated Production and Efficiency

Wistron, a global leader in electronics manufacturing, has developed digital twins of its factories to expedite the production of NVIDIA DGX and NVIDIA HGX servers. By extending its use of Omniverse, Wistron creates digital twins of data centers to test and ensure the quality, performance, and energy consumption of newly assembled systems. This approach allowed Wistron to bring its factory online in half the usual time, increasing worker efficiency by more than 50% and reducing end-to-end cycle times by 50%.

Expanding the Ecosystem to Industrial Applications

Kenmec, a leading Taiwan systems integrator, is an early adopter of Omniverse and Metropolis workflows. It provides services for major manufacturers like Giant Group. These digital twin workflows are available as a reference architecture series to support developers across the ecosystem.

NVIDIA’s collaboration with Taiwanese electronics manufacturers signifies a significant leap forward in adopting AI and digital twin technologies, driving operational efficiencies and reducing costs across the industry.

Amazon

Amazon