Its been roughly one year since StorageReview overhauled its main lab, outfitted with Eaton S-Series racks, Eaton metered and managed G3 PDUs as well as an Eaton BladeUPS Power System. The BladeUPS Power System is unique in the datacenter space, where future expansions can be approached in a modular fashion and installed without calling in an electrician. While the original design offered 12kW of capacity, growth in the StorageReview lab has grown our power demands as well. In this In the Lab article we cover the installation and upgrade process of an additional 12kW Eaton BladeUPS power module.

In our initial review of the pre-assembled Eaton BladeUPS Power System, we covered the unique design of the rack-form factor battery backup system. This system ships inside a 42U Eaton S-Series rack that has a bus-bar assembly installed. The bus-bar is designed to distribute a hard-wired 3-Phase connection to up to 6 BladeUPS modules. You can buy the rack with one to six modules preinstalled, where models fitted with less than full capacity can be upgraded in a production environment. In the StorageReview environment we pre-wired the rack with a 100A 208V 3P connection to support one additional UPS for future use.

The beauty of the Eaton BladeUPS Power System is that it can be upgraded online without bringing your production environment down, with the added bonus of doubling the power capacity of the existing hardware. That means existing the Eaton RPM we connected to the first BladeUPS module that provides power to up to six PDUs doubled the power it can draw (up to its design limits). This happens since each BladeUPS module draws power and backfeeds through the bus-bar. Once connected, each UPS can operate independently of one another, or in parallel, sharing the load regardless of where devices are physically connected. The advantage of this really starts to make sense when needing to add power capacity in a production environment. Many devices don't have dual PSUs, so if you want to upgrade the UPS, you'd need to take things offline or have already invested in a power distribution panel that supported multiple UPS feeds to switch between.

In our environment, we spent about a half an hour unboxing the BladeUPS module and battery shelf, screwing the rails into the rack, mounting the UPS and connecting it to the bus-bar. Before connecting the additional module we put our original BladeUPS into bypass mode, which directly connects devices to line power and as the name implies bypasses the UPS. Prior to switching on power we connected the appropriate CAN Bridge cable between both modules to take to one another, as well as a redundant signal wire for parallel communication. Once the correct cables were in place as well as jumpers on the back of the UPS (switching the original unit from standalone to parallel) we switched the BladeUPS system back online through the front control panel and within seconds we were up and running again.

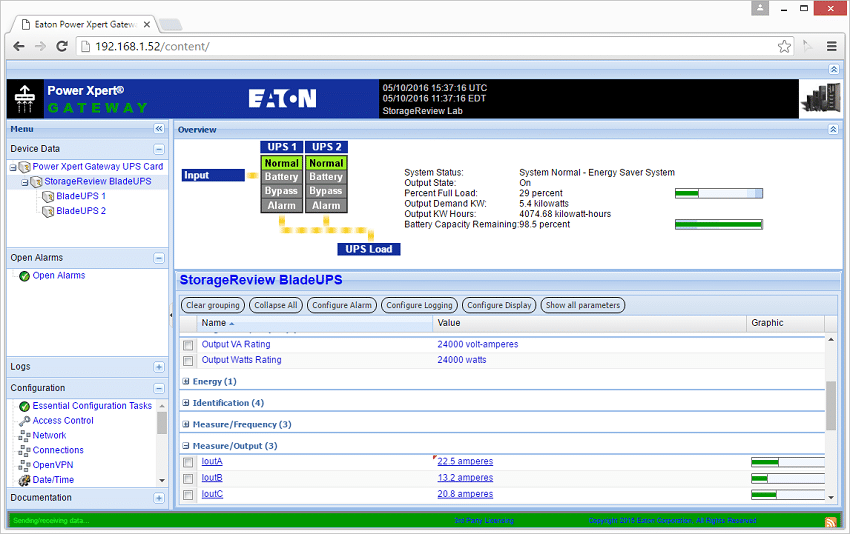

From the Eaton Power Xpert Gateway's web interface we were immediately greeted with the updated system information. This included a power rating of 24kW as well as management and monitoring capabilities of both modules through our single interface. For growing enterprise environments the Eaton BladeUPS Power System really makes things simple to expand as your demands increase without requiring forklift upgrades of existing infrastructure components.

Sign up for the StorageReview newsletter