Castrol is driving innovation in data center cooling with dielectric fluids, pushing the future of immersion cooling technology.

Immersion cooling has become a significant topic in the tech industry, especially as data centers face increasing demand for more efficient cooling solutions. Traditionally associated with automotive oils, Castrol is at the forefront of this innovation. However, Castrol is now making strides in data center cooling through its dielectric cooling fluids. We recently visited the Castrol Liquid Cooling Center of Excellence in Pangbourne, Berkshire, UK, where Castrol conducts research and development into liquid immersion cooling solutions for data centers.

The facility serves as a testing ground for Castrol’s DC-series immersion cooling fluids and various configurations of immersion tanks from leading vendors. These test cells allow Castrol to explore different cooling technologies and their impact on server components. While the focus is primarily on fluid dynamics and chemistry, the center also evaluates cables, server hardware, and material compatibility. Castrol’s comprehensive approach to testing and validating immersion technology makes it a leading figure in the future of data center cooling.

The Case for Immersion Cooling

Data centers are under growing pressure to handle an ever-increasing computational power load while reducing environmental impact. Traditional air cooling methods, even those supplemented by direct liquid cooling (DLC), are often insufficient for some of today’s high-density compute environments.

Chris Lockett, VP of Electrification and Castrol Product Innovation at BP explained, “At the moment, about 40% of power consumption in data centers goes toward cooling. Immersion cooling can drop that figure to less than 5%, significantly lowering power and water usage.”

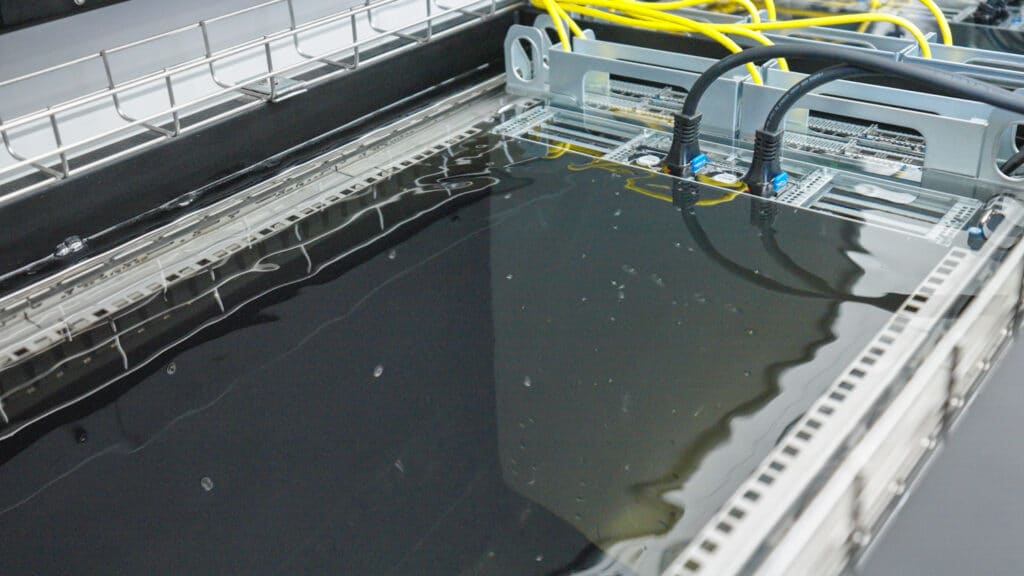

Immersion cooling, as a concept, submerges entire servers in dielectric fluid, a non-conductive liquid that absorbs and transfers heat away from the components. This approach removes the need for traditional fans, reducing power consumption and improving efficiency. As Vince and I explored the facility, it became clear that immersion cooling is no longer an experimental niche—it’s fast becoming a viable solution for high-power workloads and environmentally conscious data centers.

Exploring the Test Cells

At Castrol’s Center of Excellence, we were introduced to several immersion cooling solutions, each with a unique design and capabilities. These setups included tanks from notable vendors like GRC (Green Revolution Cooling), Submer, and Iceotope, all catering to different scales and operational requirements. For instance, GRC’s tanks are designed to handle large-scale deployments, with the ability to manage 50kW of power per tank. On the other hand, Submer and Iceotope offer more rack-specific solutions, which are ideal for modular and space-constrained environments.

A marquee feature of the test cells is the ability to conduct thorough testing in controlled conditions. The Castrol Center of Excellence facility is divided into rooms, each with temperature control, ventilation, and fire suppression systems. This allows Castrol to test various fluids and components under different environmental conditions, ensuring that the solutions they develop can withstand the rigors of real-world data centers.

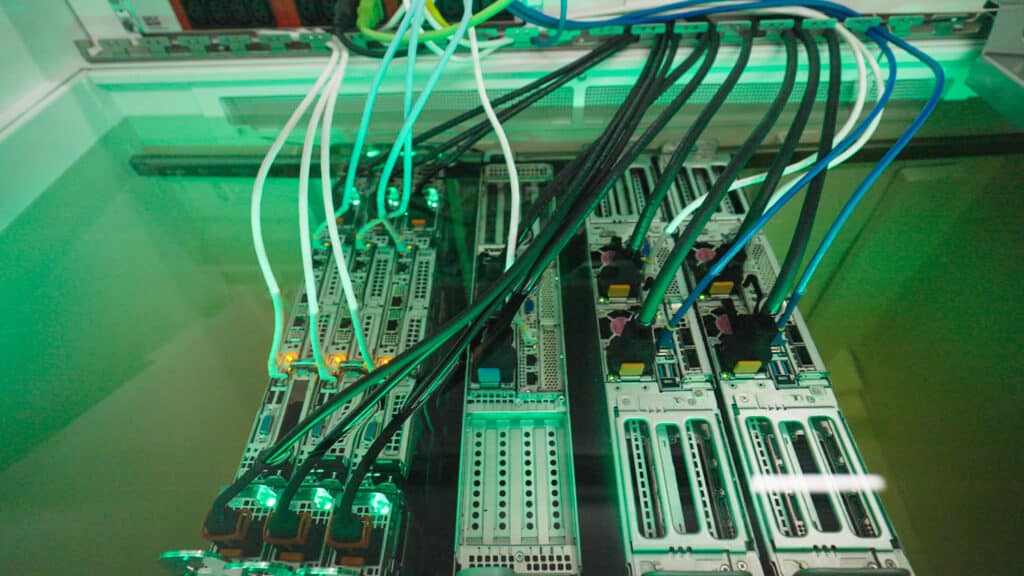

In one of the test cells, we observed GRC’s tank, which had a striking green glow due to the specific fluid Castrol was using. The servers submerged in this tank were undergoing compatibility and performance testing. Castrol ensures that every component, from CPUs to cables, can operate effectively in immersion cooling environments without degradation.

Fluid Engineering: The Heart of the System

Castrol’s DC-series fluids are at the core of its immersion cooling solutions, specifically engineered for data centers. We had the opportunity to see two of these fluids in action: DC15 and DC20. Both are dielectric fluids designed to efficiently remove heat from servers while maintaining material compatibility and fluid longevity.

Due to regional regulations, the DC15 fluid is optimized for markets requiring higher viscosity, like Asian locations. Meanwhile, the DC20 fluid is Castrol’s highest-performing option, engineered for extreme heat dissipation and higher operational temperatures. These fluids can operate in the 40°C to 50°C range, with some systems pushing temperatures as high as 70°C. This high-temperature tolerance means that, in most environments, no additional refrigeration is required, significantly reducing the operational cost and complexity of running these systems.

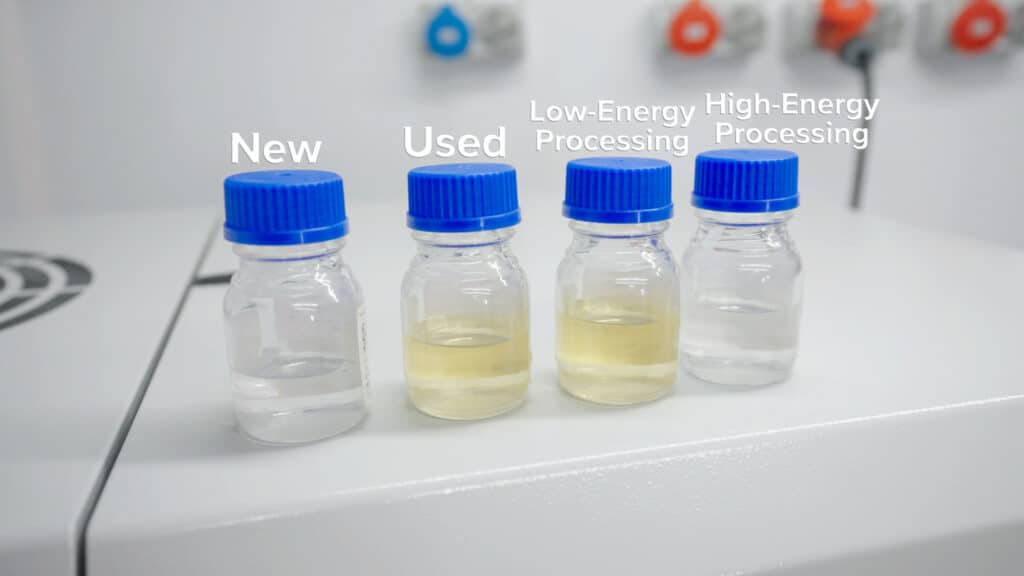

The lifecycle of these fluids is another critical aspect of their utility. According to Castrol, their fluids are designed for “fill for life” operations, meaning that under optimal conditions, the fluid can last for the entire lifecycle of the server hardware—typically 3 to 8 years. Even after this period, Castrol offers fluid recycling and reprocessing services, extending the fluid’s life and reducing waste.

Submer Mega Pods: Immersion at Scale

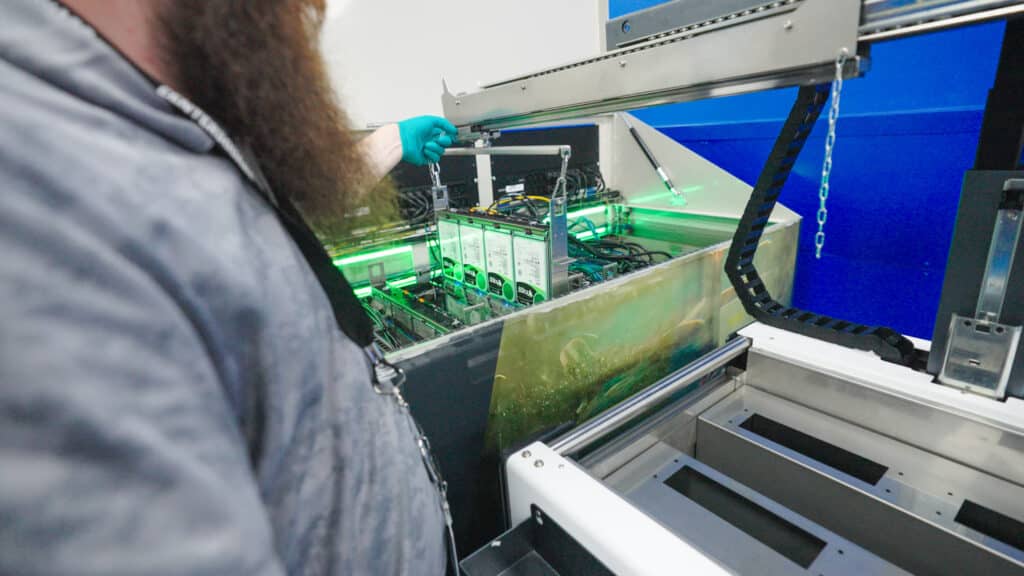

One of the highlights of our visit was the Submer Mega Pod, a modular data center solution that leverages Castrol’s immersion cooling fluid technology. Inside the Mega Pod, we found two Smart Pod XL racks, each running different fluids—DC15 and DC20. These pods represent a compact, all-in-one data center solution, complete with heat exchangers and external cooling loops that transfer heat to the surrounding environment via rooftop coolers, heat recovery systems, or geothermal solutions.

This type of system allows for incredible density and scalability while maintaining low operational noise and energy consumption. The Mega Pod can support a variety of configurations, making it an appealing option for data centers considering immersion cooling on a larger scale.

The simplicity of serviceability within the Mega Pods was also notable. Servers submerged in the cooling fluid can be easily lifted out with the help of an overhead crane, allowing technicians to service or replace components without downtime. The immersion fluids are non-corrosive and non-conductive, so even if a component is removed while still wet, it can be dried off and reused without issue.

Expanding Immersion Cooling Beyond Traditional Data Centers

While immersion cooling is gaining traction in traditional data centers, the technology holds immense potential for many other use cases. Its ability to manage high-density computing while being space-efficient and environmentally friendly makes it well-suited for non-traditional environments.

Edge Computing and Space-Constrained Environments

Edge computing brings compute power closer to the data source, reducing latency and improving real-time processing. However, edge locations often face space limitations and lack the robust cooling infrastructure available in large data centers. Traditional air cooling methods, which require bulky HVAC systems and air handlers, are not always practical in these scenarios.

On the other hand, immersion cooling can be deployed in compact, self-contained units that dramatically reduce space requirements. Solutions like the GRC ICEraq can fit multiple racks into a small footprint while maintaining high-efficiency cooling. This makes immersion cooling ideal for edge computing in telecom towers, retail stores, or remote industrial sites. Additionally, the reduced noise and lack of moving air systems make immersion cooling appealing for environments where quiet operation is critical, such as hospitals or office buildings.

Immersion Cooling for Modular Data Centers

Modular data centers—prefabricated data center modules that can be deployed quickly and flexibly, like the Submer MegaPod—are another excellent use case for immersion cooling. These data centers are often used in military operations, disaster recovery, or temporary setups where traditional infrastructure is not feasible. With immersion cooling, modular data centers can pack dense computing power into a small space while requiring less energy and infrastructure for cooling.

Castrol’s Submarine Mega Pod is an example of how immersion cooling can be used in modular data centers. These drop-in data center solutions come equipped with immersion cooling tanks and heat exchangers, allowing them to operate independently with minimal infrastructure. Given their compact design, they are ideal for scenarios where rapid deployment and high-performance computing are needed in space-limited environments.

Heat Reuse and Sustainability in Urban Areas

One of the more intriguing benefits of immersion cooling is its ability to repurpose the heat generated by servers. Unlike air-cooled data centers, which often dissipate heat into the environment as waste, immersion cooling systems can transfer heat to secondary systems, such as building heating or industrial processes.

In urban areas where land is scarce, and sustainability is a priority, immersion cooling could be integrated with district heating systems or used to warm nearby buildings. For example, the heat from an immersion-cooled data center could provide hot water or heating for residential or commercial buildings. This heat recovery model not only improves energy efficiency but also helps reduce the data center’s overall environmental footprint.

Immersion Cooling for Industrial Edge Computing

Industries such as oil and gas, manufacturing, and energy generation increasingly rely on edge computing for real-time data processing and control. These environments are often remote, harsh, contain explosive or corrosive gasses, or are subject to extreme temperature fluctuations, making traditional cooling systems impractical. Immersion cooling offers a robust solution by providing consistent and efficient heat dissipation, even in challenging environments.

In these scenarios, the rejected heat from immersion cooling could also be utilized in industrial processes. For instance, waste heat could be repurposed as a component of preheating for steam generation, water heating, or even to support on-site operations that require thermal energy. This approach aligns with the growing push for greener, more efficient industrial processes while ensuring that edge computing systems can operate reliably in rugged conditions.

Sustainable Compute for Smart Cities

As smart city projects expand, immersion cooling could play a key role in maintaining the compute infrastructure that supports everything from traffic management to public safety systems. Immersion cooling can enable dense compute nodes in smart buildings, transportation hubs, and utility systems while minimizing the cooling footprint.

These systems could also make use of waste heat for energy recovery. For instance, smart city data centers that rely on immersion cooling could contribute excess heat to power electric vehicle charging stations, heat municipal pools, or assist in waste management facilities. By doing so, smart cities can achieve their goal of integrating sustainability into their core operations while managing the data loads that power next-generation urban services.

Beyond Cooling: The Environmental Impact

In addition to reducing energy consumption, immersion cooling offers significant environmental benefits. Castrol’s fluids are designed to be fully recyclable, with no global warming potential. The company is also exploring fluid-as-a-service models, where used fluids are collected, reprocessed, and returned to the customer as fresh, high-performance liquids. This approach minimizes waste and aligns with the growing demand for sustainable data center operations.

Furthermore, immersion cooling systems can be integrated with heat recovery technologies. For instance, the excess heat generated by the servers can be repurposed for building heating or industrial applications. Castrol has even explored the possibility of using the heat to warm swimming pools, adding an extra layer of efficiency to the overall system.

Future of Immersion Cooling

As data centers expand and power requirements increase, the need for efficient and sustainable cooling solutions will only grow. Immersion cooling is emerging as one of the most promising technologies to meet this need, particularly for high-performance computing, AI workloads, and other demanding applications. While air and direct liquid cooling still have their place, immersion cooling offers a different yet compelling proposition of efficiency and scalability for the future.

The work being done at Castrol’s Liquid Cooling Center of Excellence represents the cutting-edge of this technology. The company’s focus on fluid chemistry, material compatibility, and lifecycle management makes it a key player in developing effective and environmentally sustainable immersion cooling solutions.

Our visit to Castrol’s facility in Pangbourne revealed a company deeply invested in the future of data center cooling. From engineering advanced dielectric fluids to testing immersion tanks and server components, Castrol is helping redefine how we think about data center operations. As immersion cooling continues to gain traction, it’s clear that Castrol’s expertise in fluid dynamics and material science will play a pivotal role in shaping the future of this technology.

Castrol Immersion Cooling Fluids

Engage with StorageReview

Newsletter | YouTube | Podcast iTunes/Spotify | Instagram | Twitter | TikTok | RSS Feed